The Project

The AdAM project (Advanced Automation for Manufacturing) is co-funded under the Portugal 2020 programme promoted by the Portuguese Government and the European Commission and has received the SmartEureka seal. The AdAM project targets the production of a novel solution for inline non-destructive testing (NDT) using Eddy Currents technology to identify defects on the surface and inside welding seams obtained by laser brazing. It builds on Industry 4.0 foundations by also offering modular software and middleware tools to enable the Plug & Produce concept in new and legacy systems, adding an architectural layer for the management of the production process without the need to replace existing machines.

Goals

Within the AdAM project, the following objectives were defined:

- Industry-oriented approach: Comprehensive definition of industrial requirements for fast adoption of advanced automation, tailored to the needs of current industrial challenges.

- Improve ICT adoption in automation systems: Detailed definition of software requirements that allow the transfer of current edge technology to the advanced automation environment.

- Build on standardisation: Contribution for the advancements of existing advanced automation frameworks and open standards to reach industry-ready maturity levels.

- Modular design: Development of high-value applications based on the interchangeable function block approach to demonstrate the potential and benefits of code reuse in industrial processes.

- Demonstrate the concept of Plug & Produce: Provision of software tools, services and interfaces to enable on-demand connectivity in existing hardware and applications.

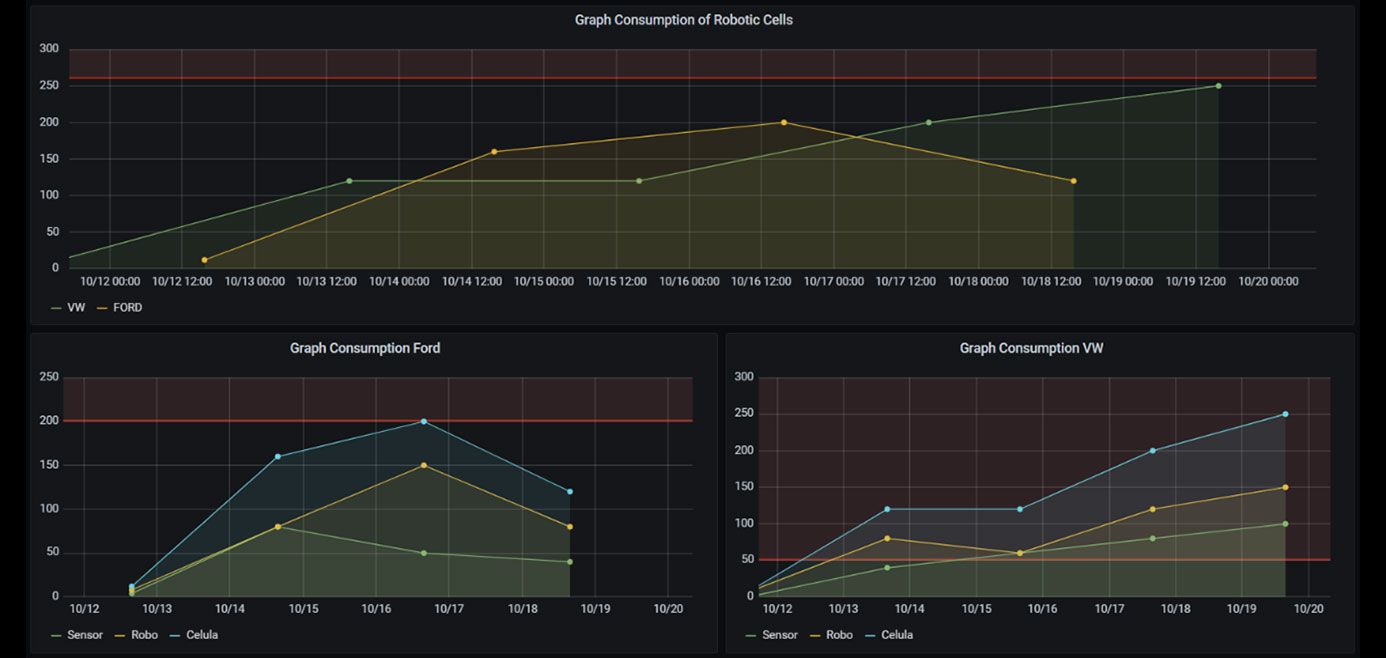

- Distributed Data Processing: Creation of a software ecosystem to deploy applications which manage large data volumes, decoupled from the low-level automation logic.

- Industrial validation and dissemination: Exploration and demonstration in real industry- relevant scenarios.

Consortium

The AdAM project is an original project of the SMART Eureka cluster, with a consortia consisting on 2 OEMs (end users of the platform – Soraluce [ES] and Volkswagen Autoeuropa [PT]), 2 engineering companies (commercial exploiters of the platform, Aldakin Gipuzkoa [ES] and Introsys SA [PT]), 2 interface centres (responsible for ensuring the excellence and innovation of the solution, IK4-Ideko S. Coop [ES] and CEiiA [PT]) and 1 university (able to transfer fundamental academic knowledge to the reality of the industries of the future, FCT NOVA – UNINOVA and UNIDEMI [PT]).

This website aims to present the results obtained during the development of the Portuguese consortium: Introsys SA, Volkswagen Autoeuropa, Universidade Nova de Lisboa (UNINOVA and UNIDEMI) and CEiiA.

Activities

Specification of industrial requirements for advanced automation applications

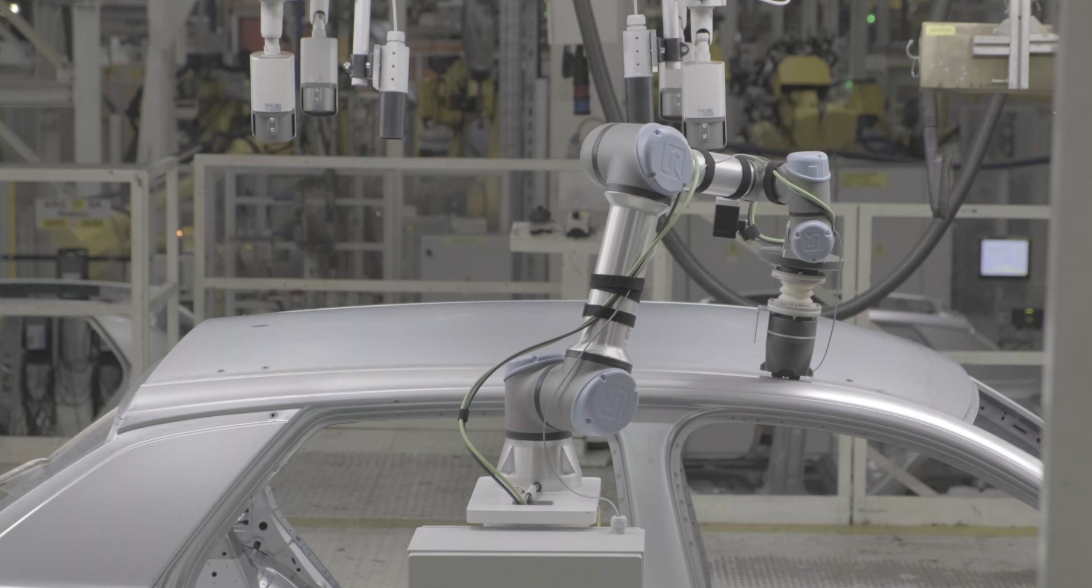

In the first phase of the project, the industrial requirements, focused essentially on the Portuguese OEM company Volkswagen Autoeuropa, were identified and defined. These influenced the definition of the software requirements that dictated the technical and operational aspects of the proposed solution.

Design of the Enterprise Information Bus (EIB) and interface devices

In this phase, efforts were carried in the development of the communication platform and the interface modules to integrate the existing devices in the factory environment.

Implementation of new generation services and applications

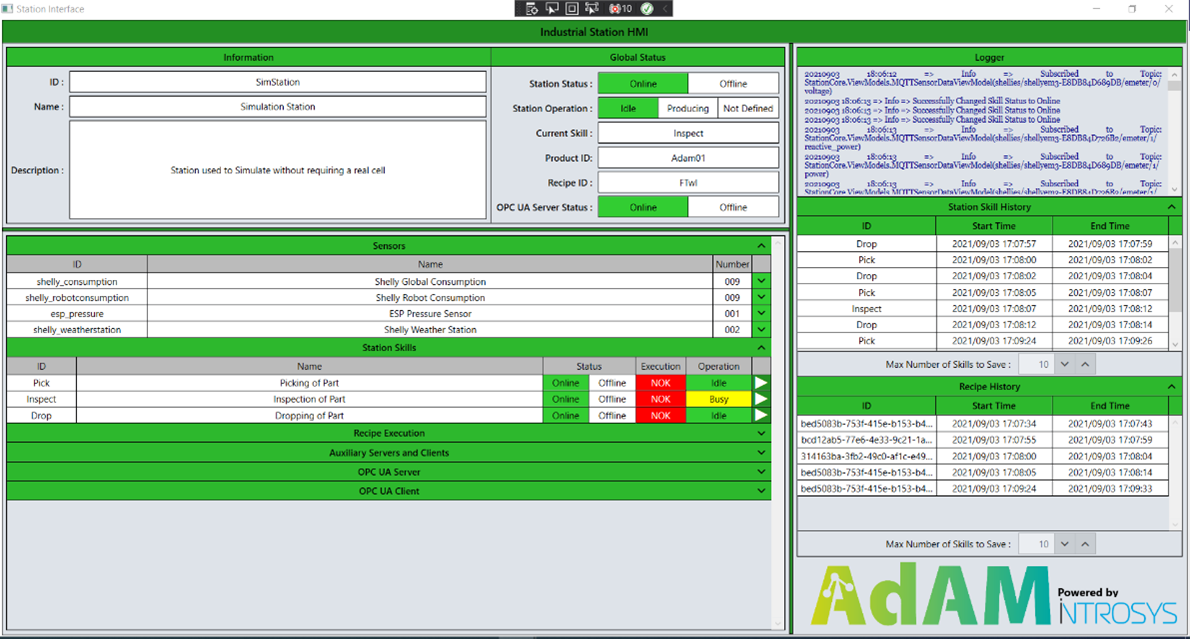

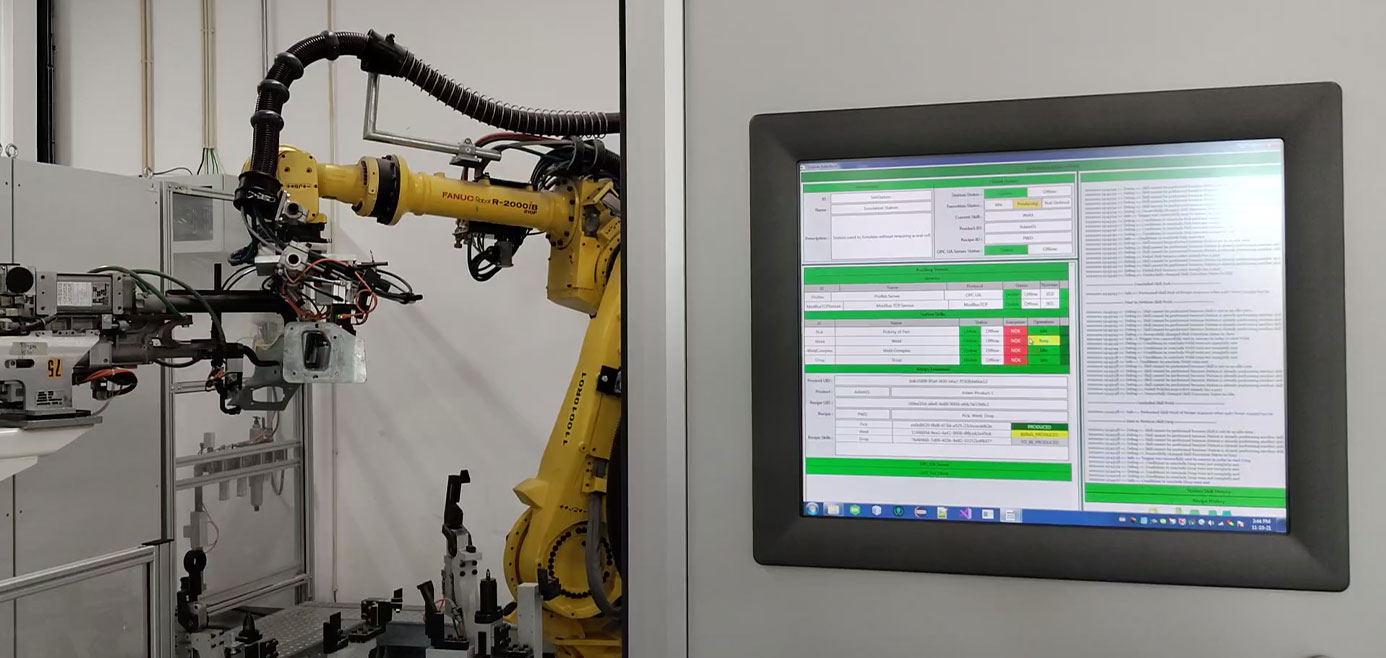

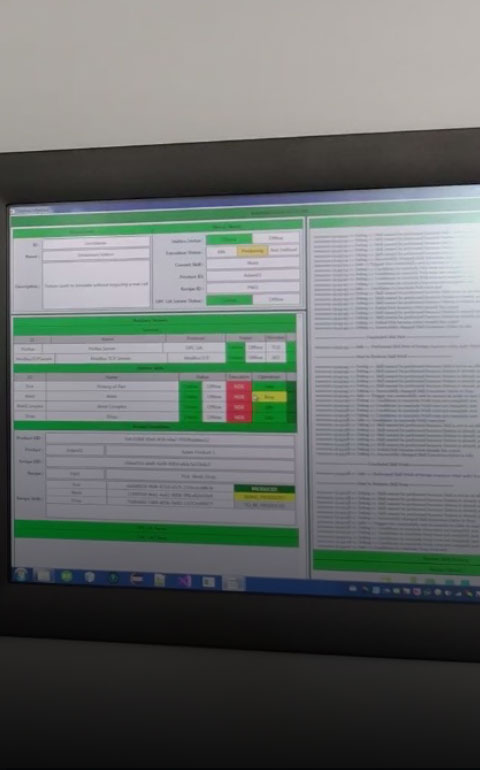

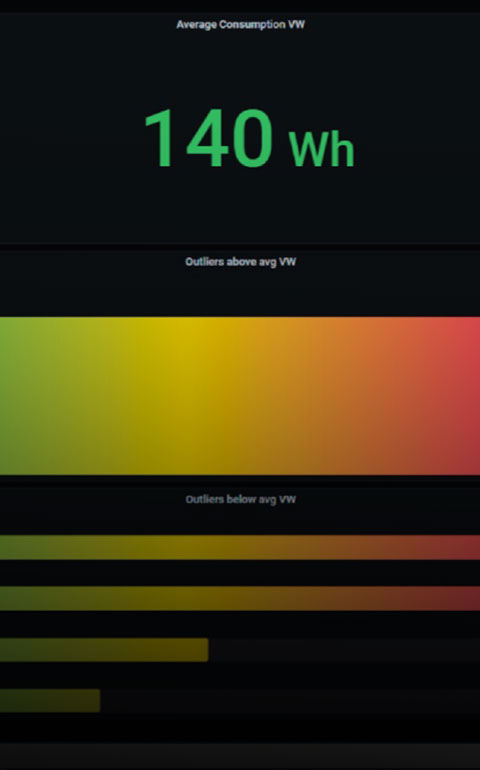

The third activity comprised the development of new services and applications for the factories of the future. Namely, a flexible logical layer for data processing; a novel probe for quality inspection based on computer vision and non-destructive testing; a generic control system for industrial automation components; an interface for the factory information system; and a graphical user interface for visualisation of production data.

System integration, validation, and demonstration

The fourth activity began with the definition of the use cases that validate the technological results of the project. Subsequently, development, integration, and validation tasks were carried in the Introsys pre-demonstrator and in the Volkswagen Autoeuropa demonstrator

Project management and coordination

Finally, the main objective of this activity was to ensure the management and coordination of the project, from project status meetings to dissemination actions.

Results

The AdAM project ended in November 2022, highlighting the following proposed achievements:

-

-

-

-

- Definition of industrial requirements for advanced automation applications;

- Design of the communication platform (EIB) and interface devices;

- Development of the data processing logic layer using the Apache Kafka tool;

- Development of an optimised low and high frequency Eddy currents probe;

- Development of a generic control system for industrial automation components;

- Development of the graphical user interface for visualisation of production data;

- Integration and validation of the Introsys pre-demonstrator;

- Integration and validation of the Eddy currents probe in the Volkswagen Autoeuropa production line;

- Creation of two videos resulting from the tests and dissemination of the project (Video1 and Video2);

- Elaboration of the flyer for dissemination of the project (Download here);

- Elaboration of a technical article showing the results of the integration in the pilot line (Download here);

- Publication of an article in the Processes Journal (Download here);

-

-

-

Events

Workshop Introsys SA

As part of the dissemination activities of the AdAM project, an online event was held on September 29, 2022 with the aim of disseminating the results of the project. You can review the event online (see here).

HANNOVER MESSE 2022

In April 2022, Introsys participated in the world’s leading trade fair for industrial technology. The ADAM project marked its presence in Germany in order to disseminate the results achieved to date.

CONTACTS & LOCATION

Address

Estrada dos 4 Castelos Lote 67

2950-805 Quinta do Anjo, Portugal

Castelo Branco Delegation

CEI – Centro de Empresas Inovadoras, Salas S2.05 e S0.02

Av. do Empresário 1,

6000-767 Castelo Branco, Portugal

GPS: N 39°48’51.8 W 7°30’24.1

Contacts

+351 212 951 499

Chamada para rede fixa nacional

© 2022 INTROSYS – Projeto ADAM. Todos os direitos reservados.

Desenvolvido por Bestsites